Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

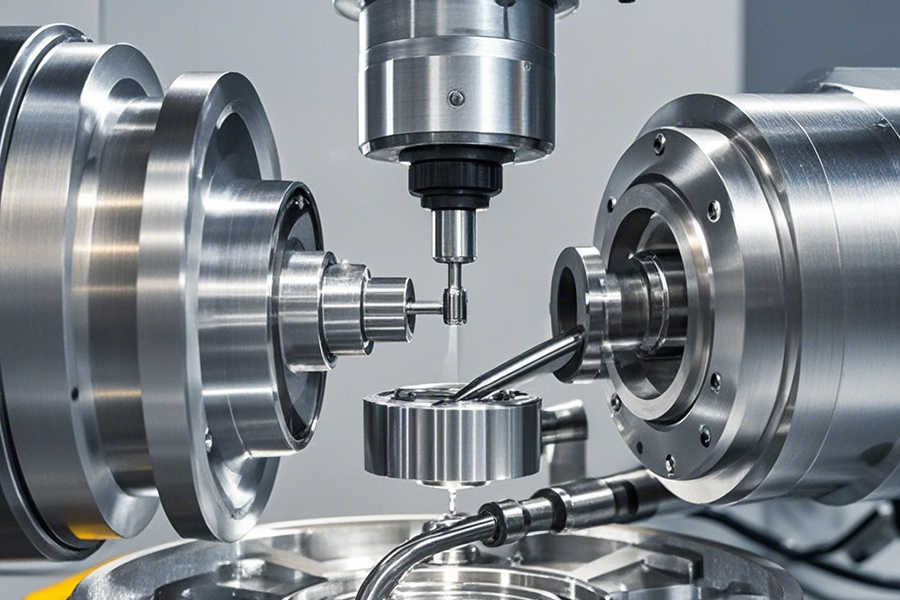

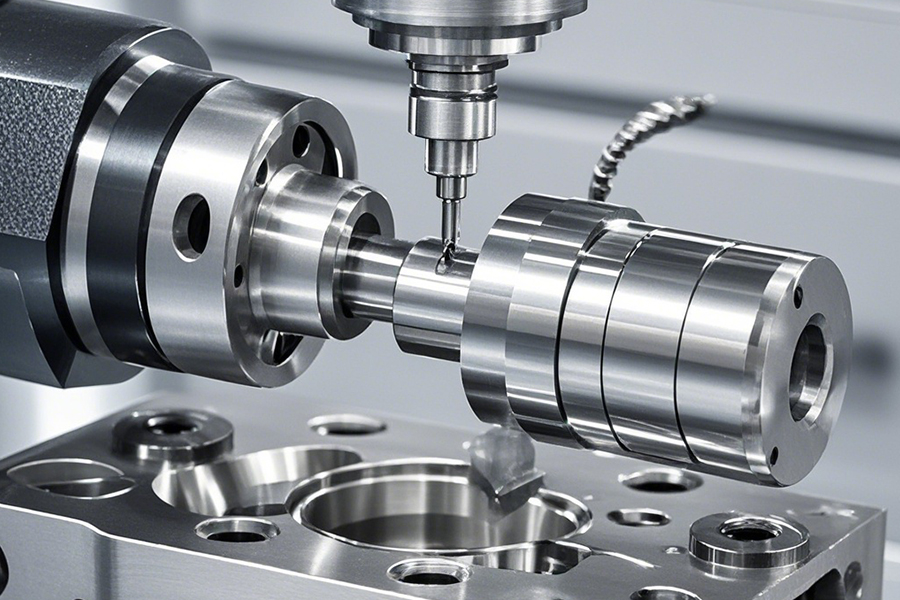

During the discharge process, the tool electrode and the workpiece electrode are not in direct contact, but the material is removed by the sparks generated by the discharge. This non-contact machining method avoids the problems of workpiece deformation and tool wear caused by cutting force in traditional mechanical machining, and is particularly suitable for machining materials with high hardness and high brittleness. Especially in the field of intelligent industry, electrospark machining technology is constantly upgraded to provide strong support for high-precision manufacturing.

Characteristics of electrospark machining

1. High-precision machining

Electrospark machining can achieve very high machining accuracy, generally up to the micron level. This is because the discharge process is local and instantaneous, and the amount of material removed by each discharge is very small, and the machining size can be precisely controlled. In addition, EDM is not affected by the hardness of the material, and can easily cope with some high-hardness materials that are difficult to process with traditional methods, such as cemented carbide and titanium alloy. In the intelligent industry, this high-precision processing capability is essential for the production of precision instruments and parts. At the same time, in the field of life sciences, some tiny medical device parts also require such high processing accuracy to ensure their performance and safety.

2. Complex shape processing

EDM can process various complex shapes of parts, such as deep holes, narrow grooves, special-shaped curved surfaces, etc. This is because the tool electrode can be customized according to the shape of the part, and the movement trajectory of the electrode is controlled by the CNC system to achieve the processing of complex shapes. Whether it is the manufacturing of high-end electronic products in the intelligent industry or the processing of special experimental equipment in the field of life sciences, the complex shape processing capability of EDM has broad application prospects.

3. No-cutting force processing

As mentioned earlier, EDM is a non-contact processing method without cutting force. This is very beneficial for processing thin-walled parts and easily deformed parts, which can avoid part deformation caused by cutting force and ensure processing accuracy. In the field of life sciences, some parts such as precision biological sample containers have extremely high requirements for processing accuracy, and no-cutting force processing can meet their needs. In the intelligent industry, it can also play an important role in the processing of some fragile electronic components.

Application of EDM

1. Automobile field

In the automotive field, EDM has a wide range of applications. For example, in the manufacture of automobile engines, some parts with complex shapes, such as fuel injectors and spark plugs, require high-precision processing. EDM can meet the processing requirements of these parts and ensure their dimensional accuracy and surface quality. In addition, in the processing of automobile chassis, some parts of special materials, such as high-strength alloy steel, can also be processed by EDM to improve processing efficiency and quality. The integration of intelligent industrial technology makes automobile manufacturing more efficient and precise.

2. Mold manufacturing

Mold manufacturing is one of the important application areas of EDM. Molds usually have complex shapes and high-precision requirements, which are difficult to meet with traditional mechanical processing methods. EDM can process mold cavities of various complex shapes, such as injection molds, die-casting molds, stamping molds, etc. Through EDM, the precision and surface quality of the mold can be improved and the service life of the mold can be extended. Driven by the intelligent industry, mold manufacturing has become more intelligent, providing high-quality molds for the production of various industries. At the same time, EDM can also play an important role in the manufacturing of some experimental equipment molds in the field of life sciences.

3. Aerospace field

In the field of aerospace, the precision and quality requirements of parts are extremely high. EDM can process various high-precision parts, such as aircraft engine blades, turbine disks, etc. These parts are usually made of difficult-to-process materials, such as high-temperature alloys, titanium alloys, etc. EDM can effectively solve the processing problems of these materials. The development of intelligent industry has brought more advanced processing technology and equipment to the aerospace field. At the same time, in the processing of experimental equipment of some special materials in the field of life sciences, EDM technology in the aerospace field can also be used for reference.

4. Medical device manufacturing

Medical device manufacturing also has very high requirements for the precision and surface quality of parts. EDM can process various high-precision medical device parts, such as artificial joints, dental instruments, etc. These parts are usually made of materials with good biocompatibility, such as titanium alloy, stainless steel, etc. EDM can ensure its processing accuracy and surface quality to meet the use requirements of medical devices. Driven by life sciences, medical device manufacturing continues to innovate, and EDM technology provides a reliable processing method for it. At the same time, the development of intelligent industry has also brought automated and intelligent production methods to medical device manufacturing.

As a precision machining technology, EDM plays an important role in modern industrial production with its unique processing principles and wide range of applications. With the continuous advancement of science and technology, EDM technology is also constantly developing and improving, especially in the fields of intelligent industry and life sciences, it will play a more important role.

Author:

Mr. Ares team

E-mail:

November 07, 2024

November 06, 2024

Envoyer à ce fournisseur

Author:

Mr. Ares team

E-mail:

November 07, 2024

November 06, 2024

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.